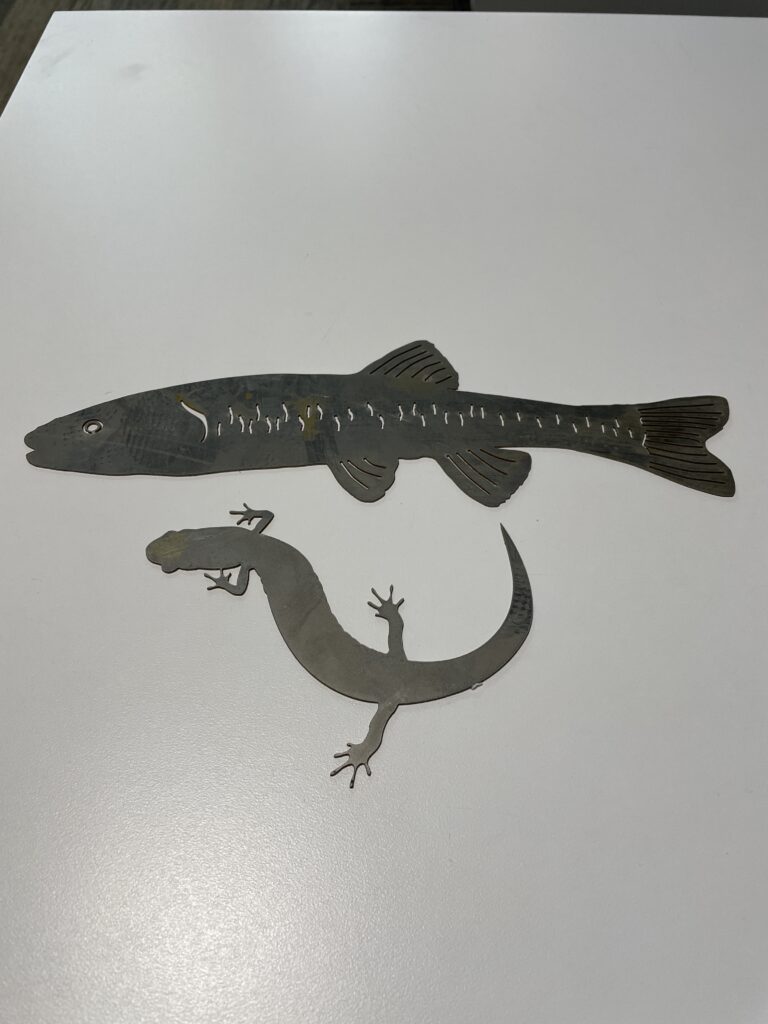

The IQ Center recently collaborated with Studio Art professor Sandy de Lissovoy on a sculpture project for his ARTS 232, Intermediate Sculpture, class.

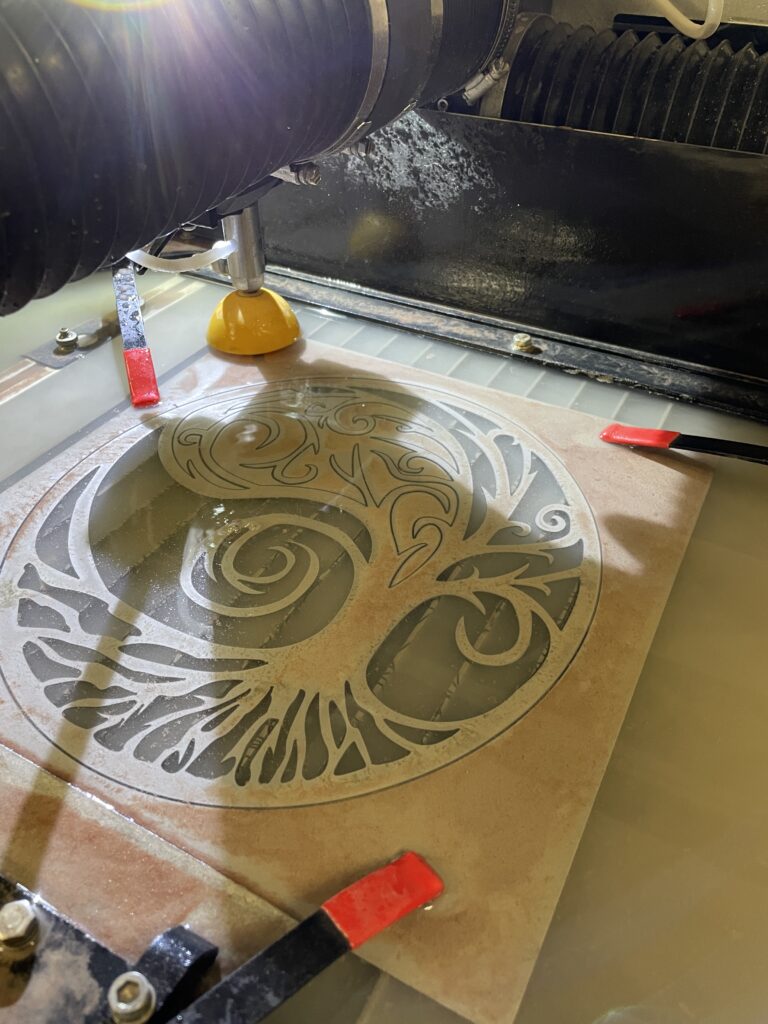

Students in the class are learning metal sculpture techniques and the new waterjet cutter in the IQ Center provides interesting options for creating metal work. The waterjet cutter uses a computer controlled, high pressure stream of water mixed with abrasive powder to cut almost any material, including steel.

In this “Digital Shapes and Metal Work Sculpture” assignment, students were instructed to create a portion of their sculpture using the waterjet cutter. This portion of the project gave them the opportunity to learn Adobe Illustrator, which is used to create the intricate vector shapes to be cut.

The IQ Center provided training and troubleshooting for the students during the project making it easy to incorporate this element into a larger project.

Want to incorporate technology like this into your Winter term course? Contact Dave Pfaff at 540.458.8044 or just stop by the IQ Center!